Because Moisture Is Just As Important As Temperature

When it comes to making a classroom a comfortable learning space, the amount of moisture in the room is just as important as the temperature. Without proper moisture control, mold and other mildew growth has the potential to appear, and a variety of health issues are at risk. Through extensive unit and component testing, Modine has ensured that their classroom HVAC equipment will never let a room become a breeding ground for the unwanted byproducts of damp spaces. Classroom Dehumidification ensures a comfortable learning environment for students and staff.

How does the dehumidification process occur?

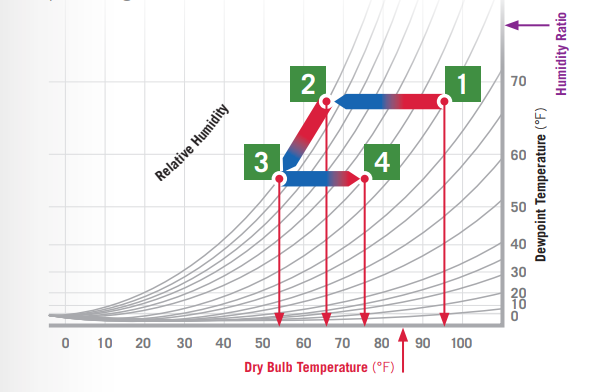

Before explaining the dehumidification process on the psychometric chart, Specific Humidity and Relative Humidity must be clearly differentiated. Specific Humidity (Humidity Ratio), also commonly called Absolute Humidity, is a quantity for characterizing the amount of moisture in the air regardless of temperature, and is measured in grains of moisture per pound of dry air. Comfort level depends more upon the Relative Humidity, which is a measure of the amount of moisture in the air relative to the maximum capacity at a specified temperature, which is given in a percentage value.

Phase 1 to 2 (Sensible Cooling)

Dry Bulb Temperature decreases from 95°F to 65°F. The Humidity Ratio stays the same but because cooler air can’t hold as much moisture as warmer air the Relative Humidity rises from 40% to 100% known as saturation.

Phase 2 to 3 (Dehumidification)

Dry Bulb Temperature continues to decrease to 54°F. The Saturation Curve is followed and moisture is

removed as the Humidity Ratio is decreased.

Phase 3 to 4 (Sensible Heating)

Dry bulb temperature is reheated to 75°F. This keeps the Humidity Ratio the same while the Relative Humidity decreases 50%. The process is finished at a lower Dry Bulb Temperature and at an acceptable Relative Humidity.

Why do you want proper dehumidification in your space?

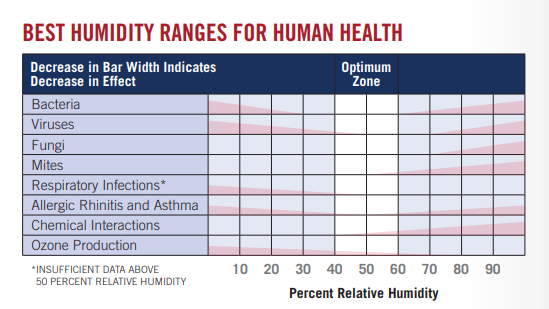

Aside from comfort, a variety of health risks arise when the Relative Humidity of a space is not properly controlled. A typical space target condition is 75°F with about 50% Relative Humidity. As seen in Figure 2, when the Relative Humidity gets outside the 40-60% range issues become more and more prevalent.

How does Modine achieve proper dehumidification?

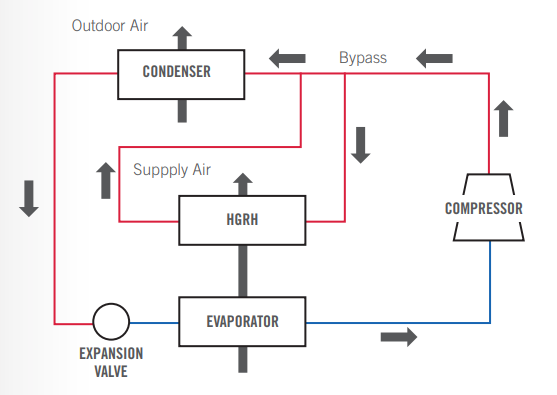

In order to properly dehumidify a classroom, it is imperative to have both the correct equipment and also a correct controls strategy. Units that don’t properly dehumidify usually end up overcooling the space because they cannot adequately reheat the supply air. In Modine HVAC equipment, dehumidification can be accomplished by the addition of a Hot Gas Reheat (HGRH) coil placed after the evaporator coil of a DX system. Hot gas from the compressor is bypassed to the HGRH coil instead of the condenser coil to take advantage of rejected heat. Overcooled and dehumidified air is reheated to a comfortable dry bulb temperature before being supplied to the space. An HGRH coil reduces the need for an energy consuming auxiliary heat source. The addition of a Head Pressure Transducer to adjust condenser fan speeds can also be added to control dehumidification.

Modine’s state-of-the-art testing facilities can replicate almost any extreme outdoor condition, ensuring that each unit will meet expectations. Labs are third-party certified, including our ventilation test cell capable of temperatures from -40°F to 140°F and Relative Humidity of 10% to 90%. Other testing labs include a semi-anechoic sound lab, dedicated geothermal and air-to-air split labs for school product testing, a climatic wind tunnel capable of duplicating almost any location on Earth, a refrigeration lab for coil testing, and a heating lab for unitary heating products.

How does a head pressure transducer add value?

Dehumidification is generally designed around a specific condition, hot and humid, but this runs the risk of overcooling a space when the ambient temperature is cooler but dehumidification is still needed; as a result more precise control is needed. Head pressure transducers can avoid this by maintaining the proper condition of refrigerant entering the HGRH coil. A sensor measures the pressure of the liquid line refrigerant, and with a PI feedback control loop, the condenser fan speed will be adjusted to regulate a proper head pressure.

What if my question isn’t covered in this handout?

If there are any questions or concerns not covered in this handout, please contact your local sales representative.

Airedale by Modine’s ViewPoint

Airedale wants every student to do their best everyday – to live, laugh, and learn in comfortable, clean, healthy environments. Air quality is central to that opportunity in our schools – now more than ever. We understand this and is equipped to respond to your air quality challenges. We recognize you want the healthiest learning environment, the safest educational institution, and the highest-performing school community. We will help you gain the maximum benefit that improved air quality and control systems can play in achieving those outcomes.

From single classrooms to campus environments, Airedale by Modine delivers smart, flexible solutions. Working in schools for over 90 years, Airedale by Modine is a trusted leader for Heat, Ventilation and Air Conditioning (HVAC) systems in educational institutions. Airedale by Modine’s legacy is your leverage. Airedale’s innovations, ideas and ingenuity will resolve your school air system quality control and ventilation challenges today – and tomorrow. Airedale by Modine – a leader in school solutions for 50 years.

Sources

1 E.M Sterling, A. Arundel, T.D. Sterling, “Criteria for Human Exposure to Humidity in Occupied Buildings,” ASHRAE Transactions 1985, Vol. 91, Part 1B, pp. 611-622.